Immersion Cooling BC Series

A Flexible, Expandable, Reliable,

and Economic Immersion Mining Solution

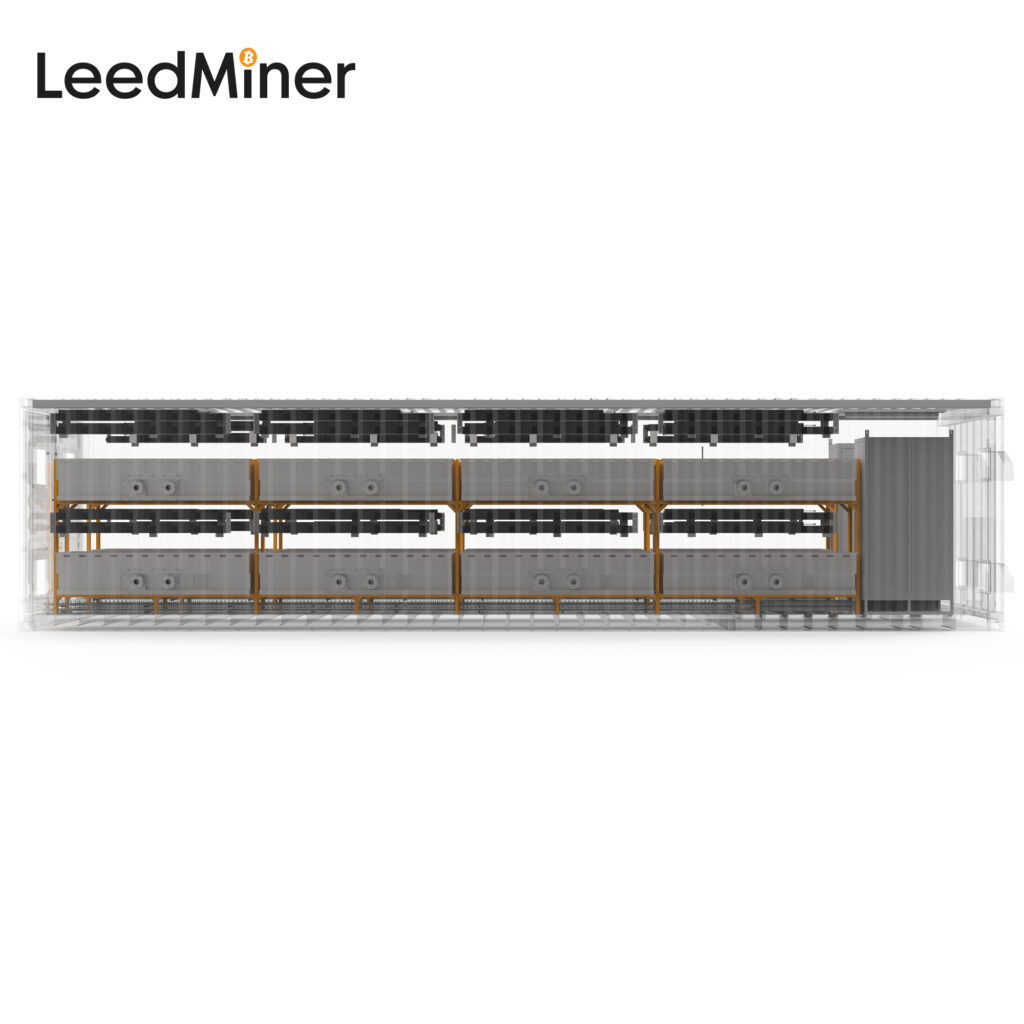

Based on LeedMiner's 2nd-generation immersion tank as a modular unit that supports 24 Antminers or 30 Whatsminers inside, all of these immersion systems are all-in-one designs. They include external dry coolers or water cooling towers, CDUs, PDCs, PDUs, piping, networking, intelligent fan speed adjustment, remote monitoring & control, and LeedMiner's proprietary coolant, providing a turn-key solution to the miners.LeedMiner offers customized design solutions to meet each customer's unique requirements. Testimonials have been received from North America, South America, the Middle East, Australia, South Korea, and Southeast Asia, demonstrating its wide adaptability.

BC40 Container Easy to Deployment

- Single-loop cycle

- Modular design system

- Extremely expandable

- Lower O&M costs

2.6MW

Maximum power load

The Pro version supports up to 2.6MW, while the Basic version supports up to 1.6MW. For more details, please refer to the specifications.

480Rigs

384 x Antminers or 480 x WhatsMiners

Accommodate up to 480 WhatsMiners.

All-Round Intelligent Management System

Integrates 3 management systems: cooling control, power monitoring and security monitoring systems.

All-Round Intelligent Management System

Integrates 3 management systems: cooling control, power monitoring and security monitoring systems.

Service Process

Have a question ?

We are here to help.

Check out the most common questions our customers have asked. Still have questions? Contact our customer support.

Our customer support is available Monday to Friday: 8am-8:30pm.

Average answer time: 24h

Products and solutions

Q: Which FogHashing immersion cooling container should I choose?

A: Your ideal FogHashing immersion cooling container will differ based on your location, weather conditions, mining facility setup, miner requirements, and daily maintenance needs. Reach out to our friendly team for personalized product recommendations and consultation.

Q: What are the main differences between the FogHashing BC series and MC series?

A: The BC series is suitable for the immersion cooling modification of air-cooled miners such as Antminer, WhatsMiner, and Avalon, while the MC series is designed for WhatsMiner M36 or M56 and supports overclocking of WhatsMiner liquid-cooled miners.

lmmersed containers

Q: What sizes and models of immersion cooling containers are available?

A: Our immersion cooling containers are designed for standard shipping containers. We offer a range of products to suit your mining machine capacity and container size, including 10-foot, 20-foot, and40-foot containers

The BC series includes BC40, BC20, BC10, and BC10Semi, while the MC series includes MC40, MC20, and MC10. The BC series also comes with Basic and Pro configuration options to accommodate various mining machine models.

Q: What is the difference between the Basic and Pro versions?

A: Our BC series products can come with Basic or Pro configuration. With the Pro version, you’ll benefit from higher electrical configuration and cooling capacity design, enabling your mining machines to run at higher power consumption for overclocking.

Q: What is the power consumption of your systems?

A: Our systems require varying amounts of power to operate essential parts, includincooling fans, water pumps, oil pumps, and so on.

As an example, the BC40 Basic system’s self-power consumption, excluding miners, is approximately 96 kW.

Q: What is the difference between maximum power load and cooling capacity?

A: A system’s maximum power load is related to the specifications of the distribution cabinet and represents the maximum power consumption supported by the system. Cooling capacity is related to the specifications of the cooling device and represents the maximum cooling capability supported by the system.

As an example, the BC40 Basic system is equipped with two 1200Ax2 distribution cabinets and supports a maximum power consumption of 1.58 MW. The electrical configuration of the system is designed with redundancy to ensure an adequate margin of safety. Cooling capacity is designed based on a power consumption of 3.5 kW per miner and provides 1.34 MW of cooling under standard working conditions.

Q: Approximately how much oil is used per container?

A: The total oil consumption of our containers can be calculated based on the number of immersion cooling tanks.

On average, each immersed cooling tank consumes about 750-800 liters of oil. However, consumption may vary for different miners. For instance, the BC40 is configured with 16 tanks, requiring approximately 13,000 liters of oil.

Coolers

Q: Why are multiple coolers used for immersion cooling?

A: The FogHashing immersion cooling system adopts a modular and single-loop circulation design. Each pair of immersed cooling tanks, comprised of wo inlets and two outlets, uses one cooler for heat dissipation.

For example, there are 16 immersed cooling tanks inside our BC40, and the system is equipped with eight coolers. Our design allows each tank to operate independently and have its circulation loop opened or closed. This design achieves modular operation of the system, maintains high uptime, and significantly reduces downtime caused by system maintenance.

Q: What are the options for coolers?

A: Coolers can be selected based on different environmental conditions, mining facility setups, and daily maintenance requirements. These options include both air coolers and closed-loop cooling towers.

Q: How does an air cooler cool the coolant?

A: An air cooler cools the dielectric liquid by exchanging heat with the air. The hot dielectric liquid is transported to the air cooler through pipes. Once there, fans blow the air into the cooler and exchanges heat with the pipes, thereby reducing the temperature of the dielectric liquid.

Q: What kind of environment is suitable for an air cooler?

A: Based on the performance characteristics of air coolers, which use air for heat dissipation of the dielectric liquid, air coolers are suitable for use in dry, humid environments with low temperaturesor those with limited water resources.

Q: How does a closed-loop cooling towerwork?

A: A closed-loop cooling tower reduces the temperature of the dielectric liquid by exchanging heat between water and air. The hot dielectric liquid is transported to the cooling tower through pipes, where water is sprayed onto the fillings and pipes.

With the assistance of fans, the tower then introduces air to exchange heat with the water, thus dissipating heat from the pipes carrying the dielectric liquid and lowering its temperature.

Q: How much water does a cooling tower consume?

A: The amount of water needed will depend on the system you use. As an example, the BC40 water cooling tower circulates and reuses 50 tons of water per hour. Under extreme high-temperature and overclocking conditions, the water consumption does not exceed 1%.

Calculated at a maximum of 1% water consumption under extreme conditions, each cooling tower requires a maximum of 0.5 tons of water per hour. There are eight water cooling towers in a 40-foot container, so a maximum of four tons of water per hour is required.

Q: What kind of environment is suitable for a closed-loop cooling tower?

A:Based on the performance characteristics of closed-loop cooling towers, which use water for heat dissipation of the dielectric liquid, these towers are suitable for use in dry, high-temperature environments with sufficient water resources.